Zhuzhou Weilai New Material Technology Co., Ltd.

Zhuzhou Weilai New Material Technology Co., Ltd. is located in Tiantai Jingu National Enterprise Incubation Park, Zhuzhou City, Hunan Province. It is committed to the research and development and manufacturing of high-performance heterogeneous refractory metal composite materials, including high-performance X-ray tube anode targets, plasma spraying nozzles and electrodes, resistance welding electrodes, etc., which are mainly used in medical equipment, plasma spraying and automobile manufacturing industries. The company provides customized solutions for customers and is a technology-led high-tech enterprise integrating R & D, production, sales and service.

The company takes R & D as the foundation and innovation as the soul; the core members of the team have many years of experience in technology development and innovation in metallurgy and materials science related fields, and have rich technology accumulation and industry experience. At the same time, the company works closely with the Powder Research Institute of Central South University to promote "industry-university-research" and build a collaborative innovation platform based on market demand.

Adhering to the business philosophy of "striving for perfection and creating value for customers", the company focuses on the subdivision of refractory metal materials industry, constantly optimizes the process adaptability of products, develops more guiding supporting products in the industry, provides more reasonable overall solutions for users, and makes unremitting efforts to realize the vision of "becoming an excellent enterprise in the field of new materials.

Company establishment

Product Category

Number of machines

Products are exported to many countries and regions

Patent Qualification

With strict product production technology and exquisite production technology, we have won the trust of our customers.

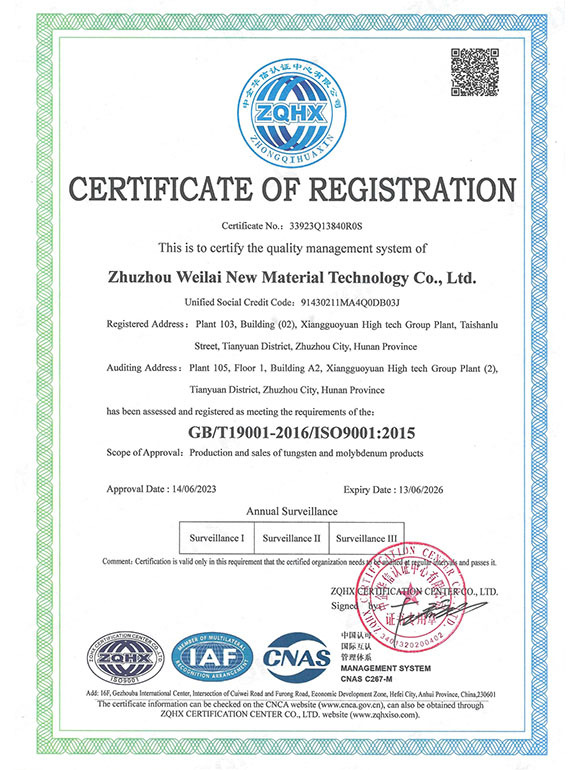

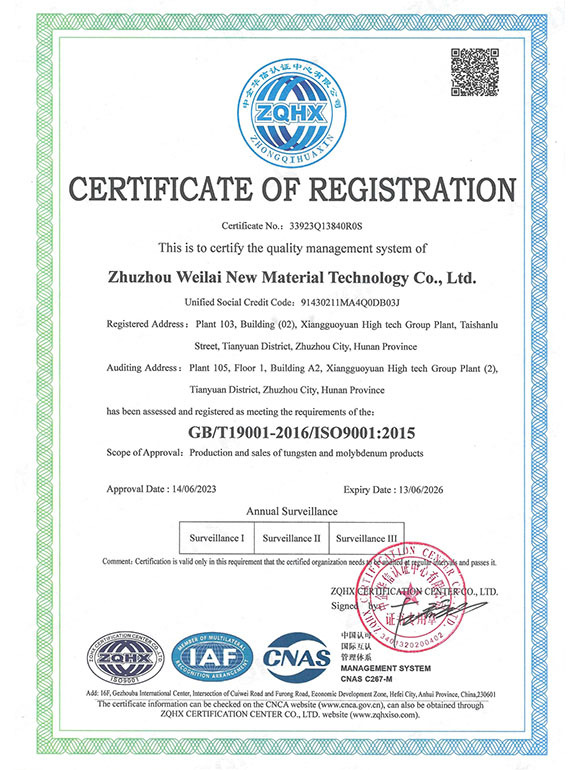

ISO9001

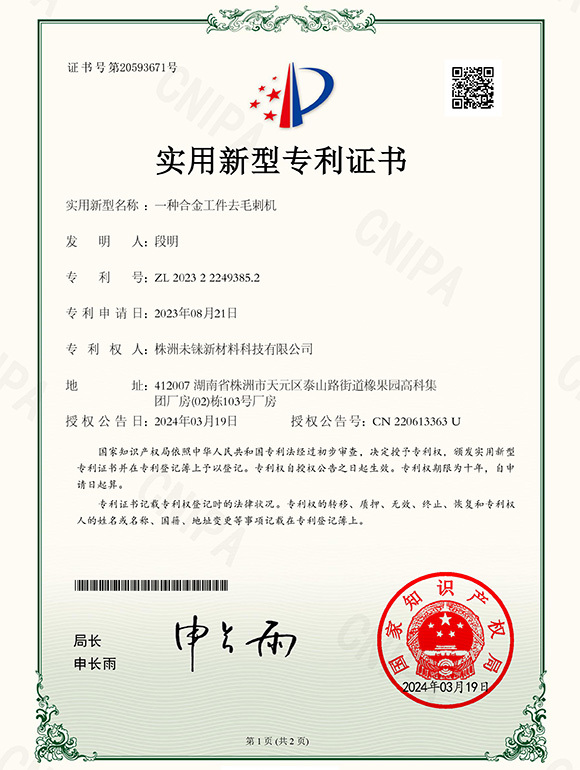

Utility model patent (a deburring machine for alloy workpieces)

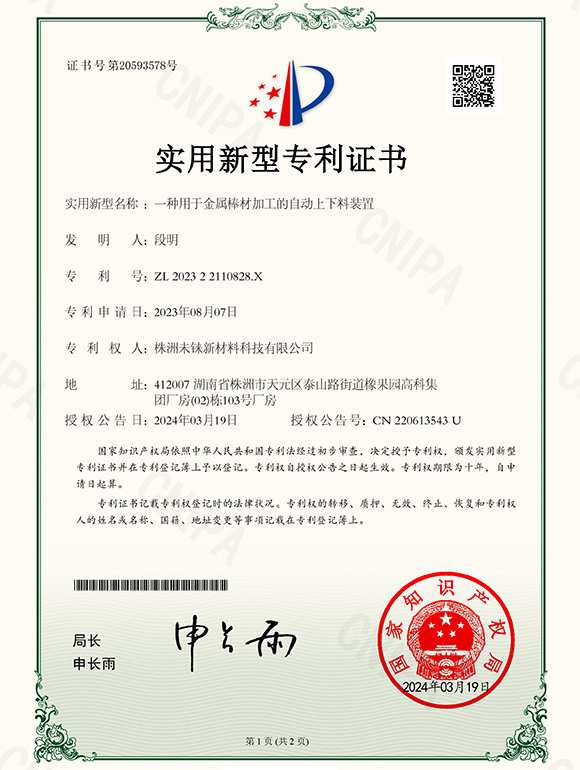

Utility model patent (an automatic loading and unloading device for gold bending bar processing)

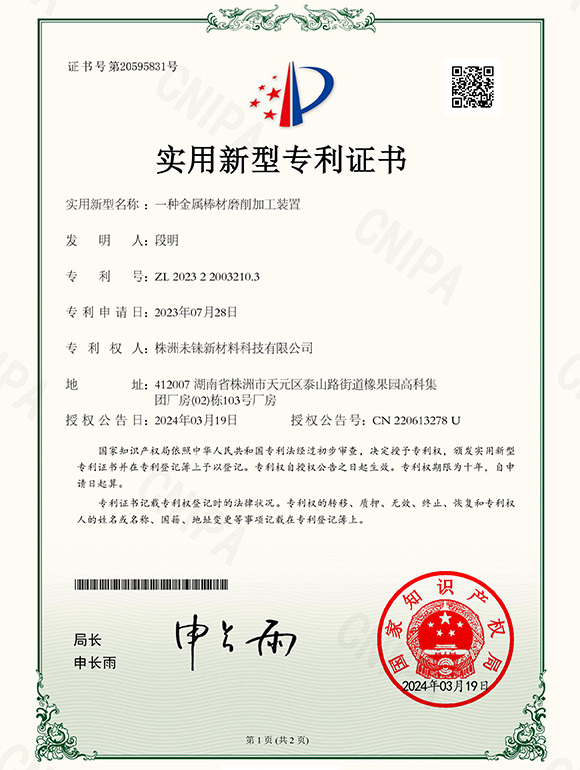

Utility model patent (a metal bar grinding device)

Patent Qualification

With strict product production technology and exquisite production technology, we have won the trust of our customers.

ISO9001

Production Equipment

Our company has 15 lathes and 4 milling machines, which provide strong processing capacity for our production, can meet the various processing needs of customers, and provide high-quality products and services.

CNC lathe group

Vacuum purified gas

Heat treatment furnace

Machining center

Production Equipment

Our company has 15 lathes and 4 milling machines, which provide strong processing capacity for our production, can meet the various processing needs of customers, and provide high-quality products and services.

CNC lathe group

Quality assurance, careful design

technology-led high-tech enterprise

The company is equipped with advanced testing equipment, including three-coordinate measuring instrument, spectrometer, hardness tester, image measuring instrument, etc. These devices can accurately measure and analyze the size, shape, hardness, chemical composition and other key indicators of the product to ensure that the product meets the design requirements.

A strict quality management system has been established, following the ISO 9001 quality management system standard. We strictly implement the quality management process, including the whole process control from raw material procurement to product manufacturing, to ensure that every link meets the quality requirements.

considerate service, reliable quality

Committed to the R & D and manufacturing of high-performance heterogeneous refractory metal composites

We have an experienced and skilled quality inspection team. They find and solve quality problems in time by conducting comprehensive inspection and testing of products. At the same time, they also conduct continuous training and learning to keep up with the latest technology and standards in the industry.

We have developed a strict quality control process, including raw material inspection, production process inspection and final product inspection. We sample each batch of raw materials to ensure that they meet quality standards. In the production process, we carry out online inspection and sampling inspection to ensure that the products meet the quality requirements at each production stage. Finally, we conduct a comprehensive inspection of the final product to ensure its quality.